Sanli Village, Houzhai Township, Erqi District, Zhengzhou City

+8613503816943

+8637163295496

Introduction of black silicon carbide is black silicon carbide is commonly known as "Emery", with the Moh’s hardness of 9.2-9.8 and the density of 3.06-3.20g/cm³, the melting point of about 2700℃. Silicon carbide has high hardness, high strength, high toughness, high chemical stability, corrosion resistance, high temperature resistance, impact resistance, good thermal conductivity, semiconductor and other characteristics. As a material widely used, it also has a new application to be developed in the field of new technology.

At present, it is mainly used in the following fields:

1>Electronic products, ceramic materials, semiconductors

2>Abrasive tools, grinding, polishing

3>Refractory materials

4>Metallurgy, casting, Deoxidizer

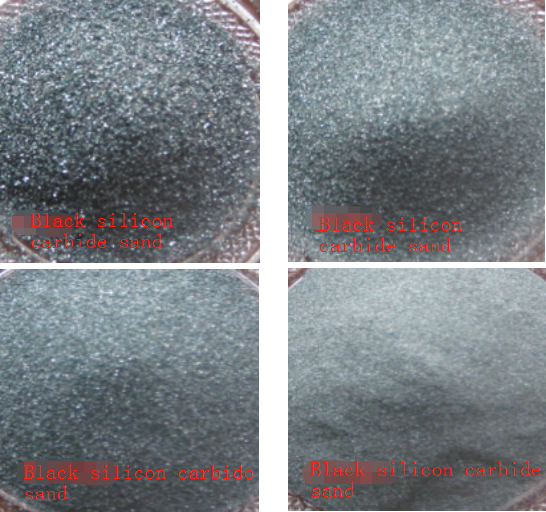

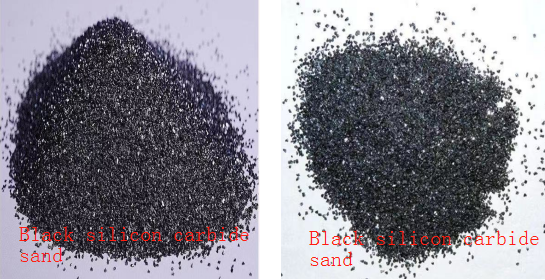

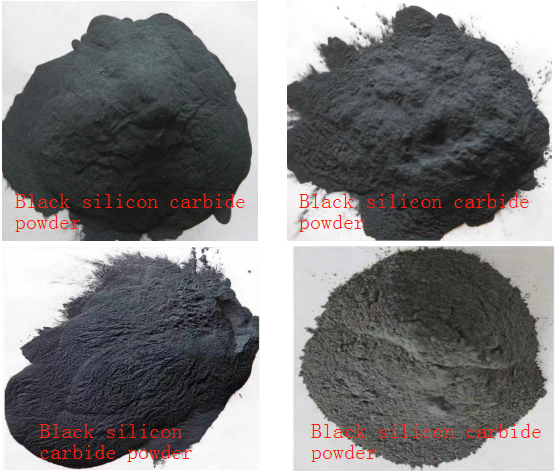

The product pictures are as follows:

The available particle size of black silica carbide sand

|

F20 |

F24 |

F30 |

F36 |

F40 |

F46 |

F54 |

F60 |

F240 |

|

F70 |

F80 |

F90 |

F100 |

F120 |

F150 |

F180 |

F220 |

F280 |

The available particle size of black silica carbide power

|

F320 |

F360 |

F400 |

F500 |

F600 |

F700 |

F800 |

|

F1000 |

F1200 |

F1500 |

F2000 |

F3000 |

F4000 |

F6000 |

Brown corundum sandAvailable particle size F6、F10、F12、F16、F24、F30、F36、F60、F100

Introduction of white corundum abrasive is made of quality aluminum oxide powder by melting at high temperature above 2000℃in the arc furnace and then cooling.

Green silicon carbide is made of petroleum coke and high-quality silica, with salt as an additive, by smelting at a high temperature in a resistance furnace. Af